Description

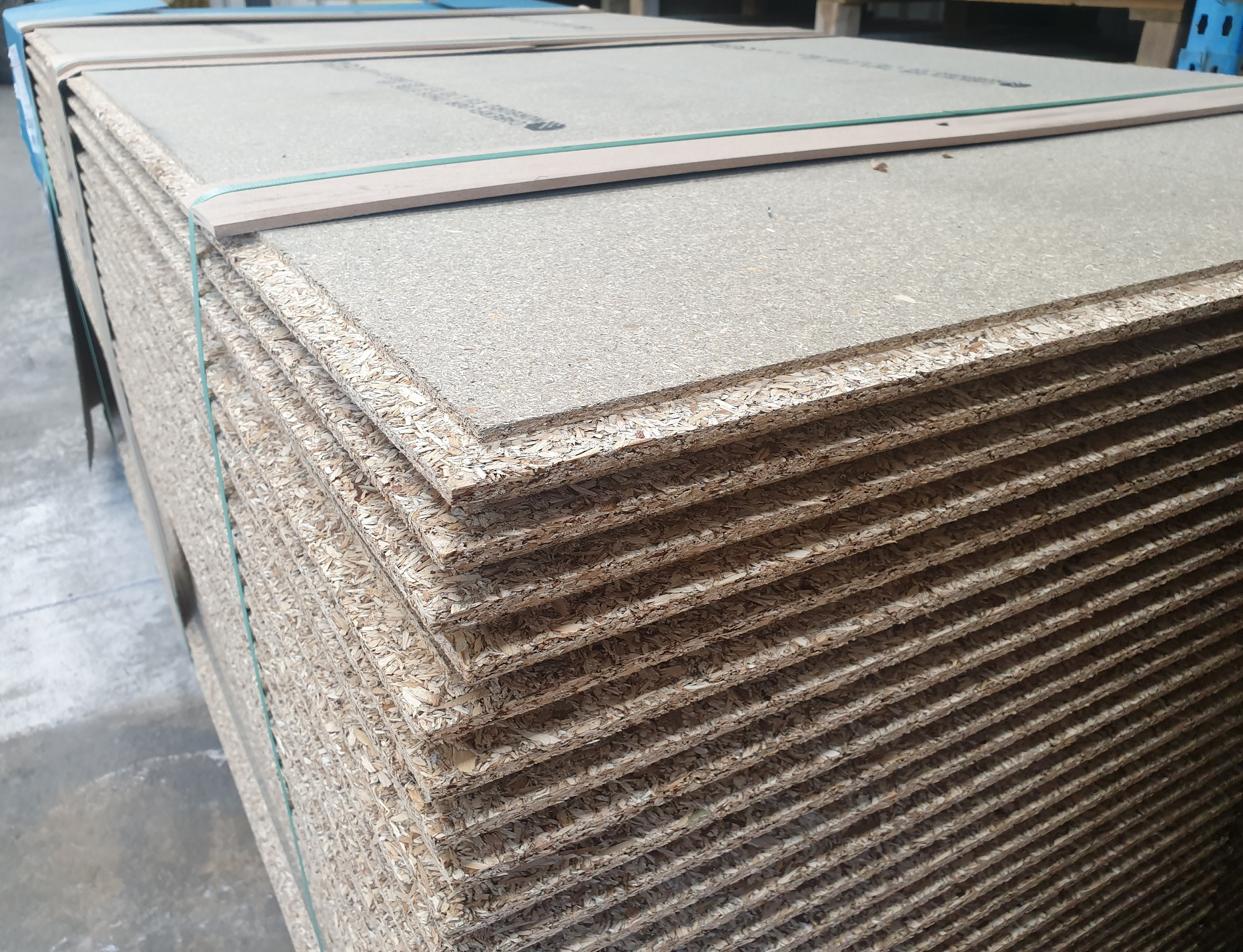

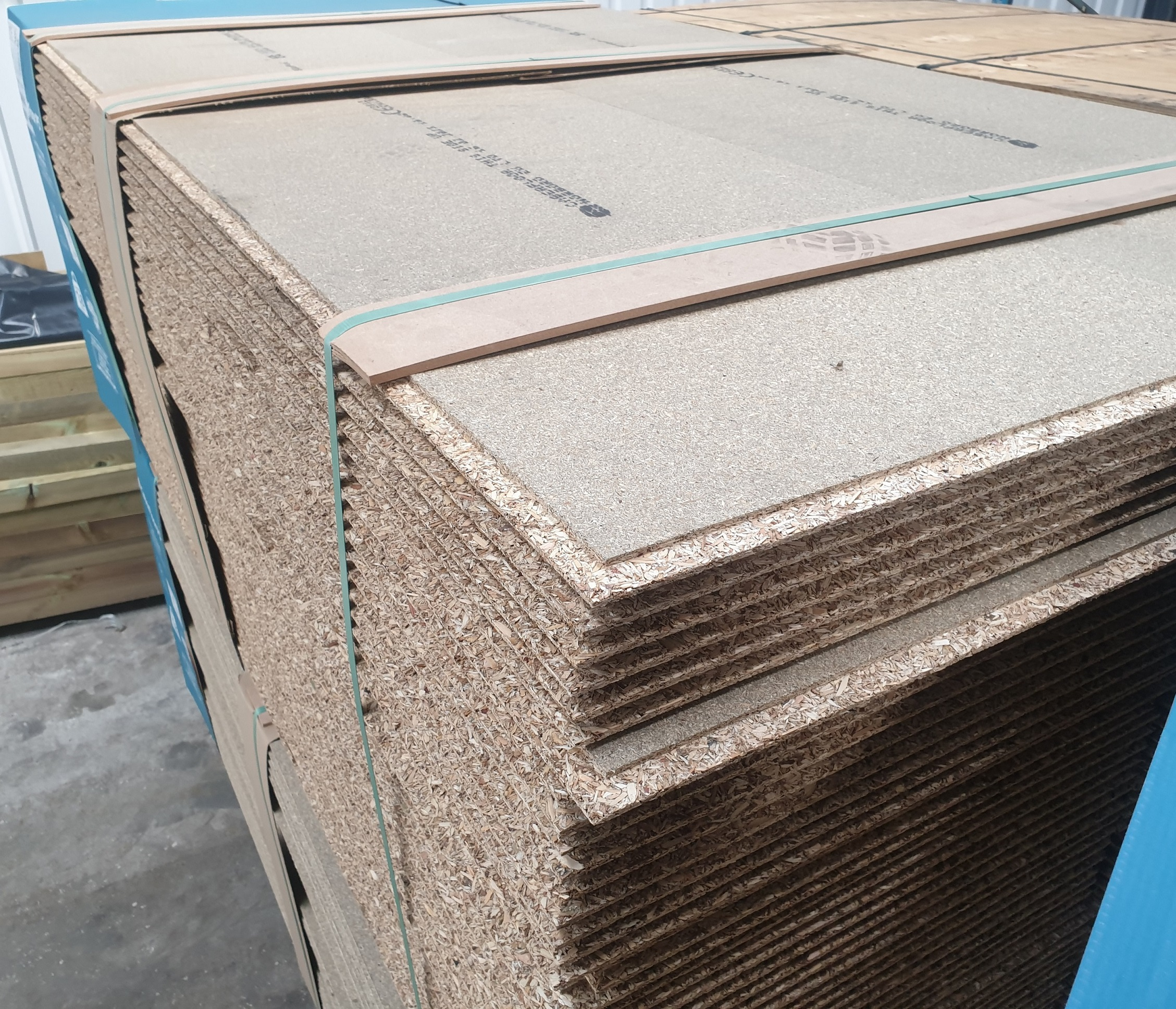

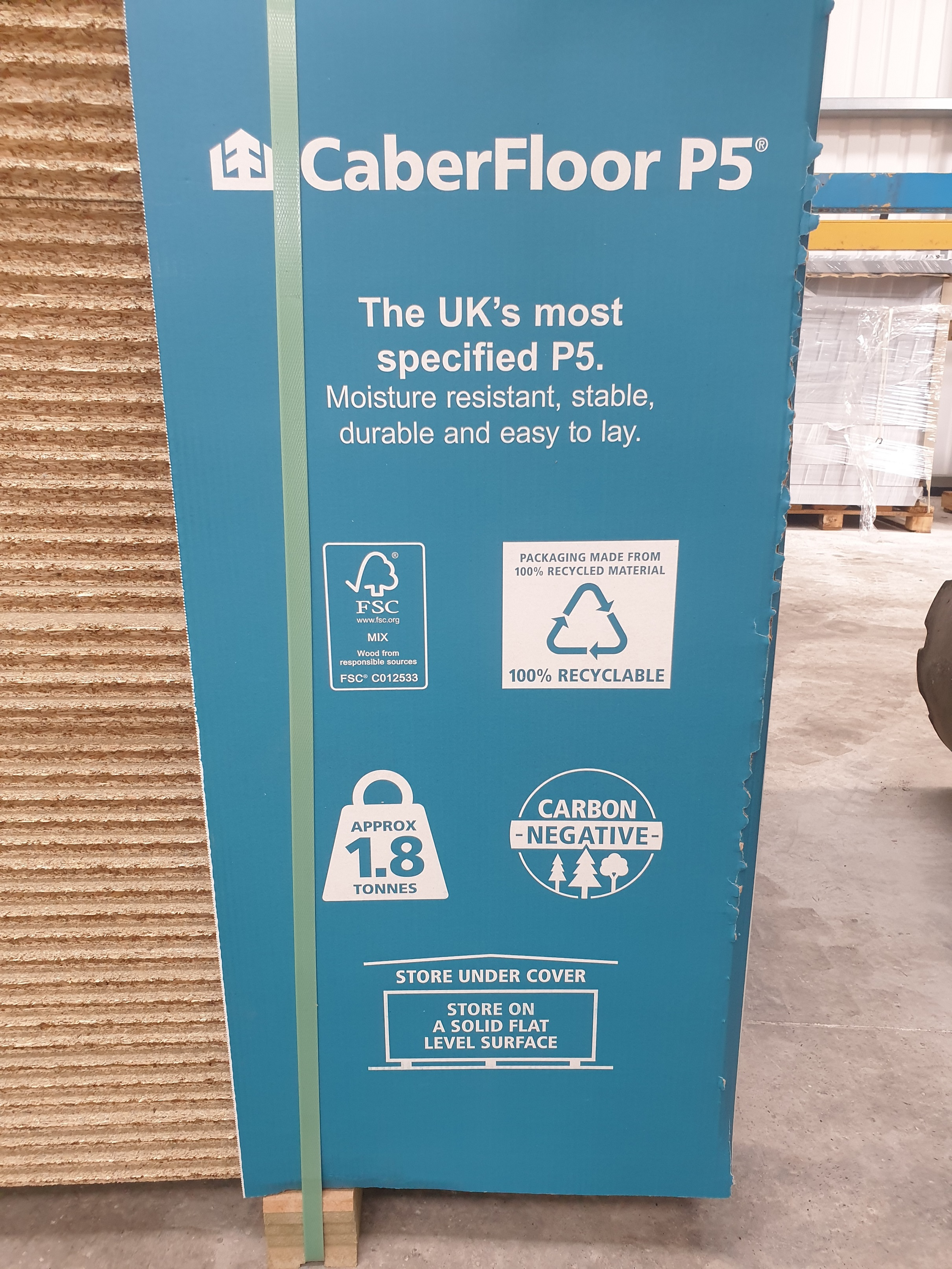

A high-density particleboard designed specifically for flooring applications in humid conditions.

Features and benefits:

- Can be used effectively on acoustic battened floor systems.

- Durability is achieved by using highly moisture resistant resin systems.

Perimeter expansion gap:

- It is important to leave an expansion gap of 2 mm per metre run of board between the edge of the floor and the perimeter wall or any solid abutment (minimum gap 10 mm).

- For larger areas it is necessary to incorporate intermediate expansion gaps to provide the necessary allowance for possible movements, particularly in corridor applications.

- Attention must be paid to maintaining expansion gaps at all times during construction.

Expansion and contraction provision:

- An expansion provision should be allowed of 2 mm per metre plus 1 mm for every metre above 12 m of the width or breadth of the area.

Soft and resilient floor coverings:

- When thin or shiny floor surface materials are laid over CaberFloor these materials may allow board joints to show through, particularly after trafficking. Prior to laying such materials, the CaberFloor joints should be checked for level. It is permissible to sand off any raised areas not exceeding 1 mm. For raised areas greater than 1 mm, additional levelling materials are required. Thin plain coloured carpets or vinyls or those with a high sheen tend to show small irregularities to a greater degree.

- For thin vinyls and tiling, it is recommended that a plywood overlay (4 mm) is fixed in position, staggering joints so as not to coincide with CaberFloor joints. The plywood should be fixed every 100 mm using appropriate nails or screws around perimeter and 150 mm apart elsewhere, ensuring they do not protrude above the surface. Adhesive manufacturer advice should be followed for priming of new surfaces. Usually, this involves a coat of dilute PVA emulsion, e.g. Uni-bond.

Ceramic tiling:

- Tiling onto CaberFloor should be undertaken only in joisted or fixed floor constructions.

- Noggins should be used between the joists at 300 mm centres and the surface provided for tiling should be 15 mm exterior grade plywood screwed to joists and noggins at 300 mm centres. Existing boards can therefore be overlaid with 15 mm exterior grade plywood to provide the necessary rigidity for a tiled surface.

- Length of fixings should be 2.5 times overall board thickness. A tile adhesive is the recommended bond material - cement/ sand mortars are not recommended.